Natural gas recovery with mobile compressor

Cost savings on your side

NET4GAS owns and operates a mobile gas recovery compressor that enables the safe recovery of gas from the gas pipeline section under repair either to an adjacent section of the same gas pipeline or to another gas pipeline. NET4GAS offers the mobile compressor also to external clients. Gas recovery from the pipeline section before its repair can provide the operator or owner with considerable savings while preventing greenhouse gas discharge into the atmosphere. Under favourable technical conditions, the owner or operator can achieve considerable financial savings even in cases when the compressor is deployed for less than 24 hours.

Provided that there is enough time for mobile compressor deployment, the pressure in the source gas pipeline can be reduced down to approximately 5 bar. When the time for mobile compressor deployment is limited, the residual pressure in the source pipeline section will be higher than 5 bar; however, gas recovery can still generate financial savings.

The entire mobile compressor unit consists of a gas engine, a compressor, coolers, fittings, and a metering and control system with safety elements. The design pressure of the compressor is 75 bar – the compressor can increase pressure on the discharge side (target gas pipeline) up to 75 bar while reducing the pressure on the inlet side (source gas pipeline) down to approximately 5 bar.

The equipment is installed on a truck trailer and complies with all EU road traffic regulations. No special permit is required for compressor transport due to its standardized dimensions and weight - only the towing vehicle and a paved road to the recovery point are needed. The mobile compressor is connected with a temporary pipe system to inlet and discharge flanges of the gas equipment at the recovery point. Gas recovery begins after the valves physically isolating the recovered gas pipeline section are closed. As soon as the recovery is completed, the gas pipeline can be depressurized, vented, and the planned repair can commence.

The mobile compressor complies with the European standards applicable to equipment operated in explosive environments. Compressor operation is monitored by an automated control system during recovery. This system safely shuts the compressor down if any deviation in the monitored operating parameters is identified.

Advantages of mobile compressor deployment:

- Savings in the form of recovered natural gas

- Lower emissions of greenhouse gases

- High mobility of the equipment

- Simple and quick connection

- The unit is driven by natural gas from the pipeline

- Lower noise level compared to gas discharge

Examples of mobile compressor deployment:

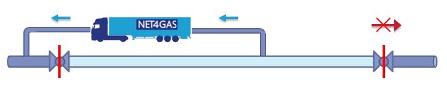

A. Natural gas recovery between two sections of the same gas pipeline

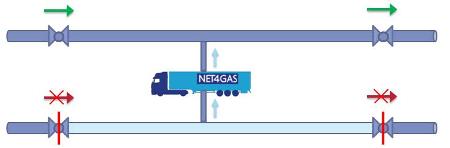

B. Natural gas recovery from a section of one gas pipeline into a parallel gas pipeline

Downloads:

Contact person:

Jan Dominik

Senior Manager, Special Works & Technologies

E: specialmaintenance@net4gas.cz

T: +420 220 225 133